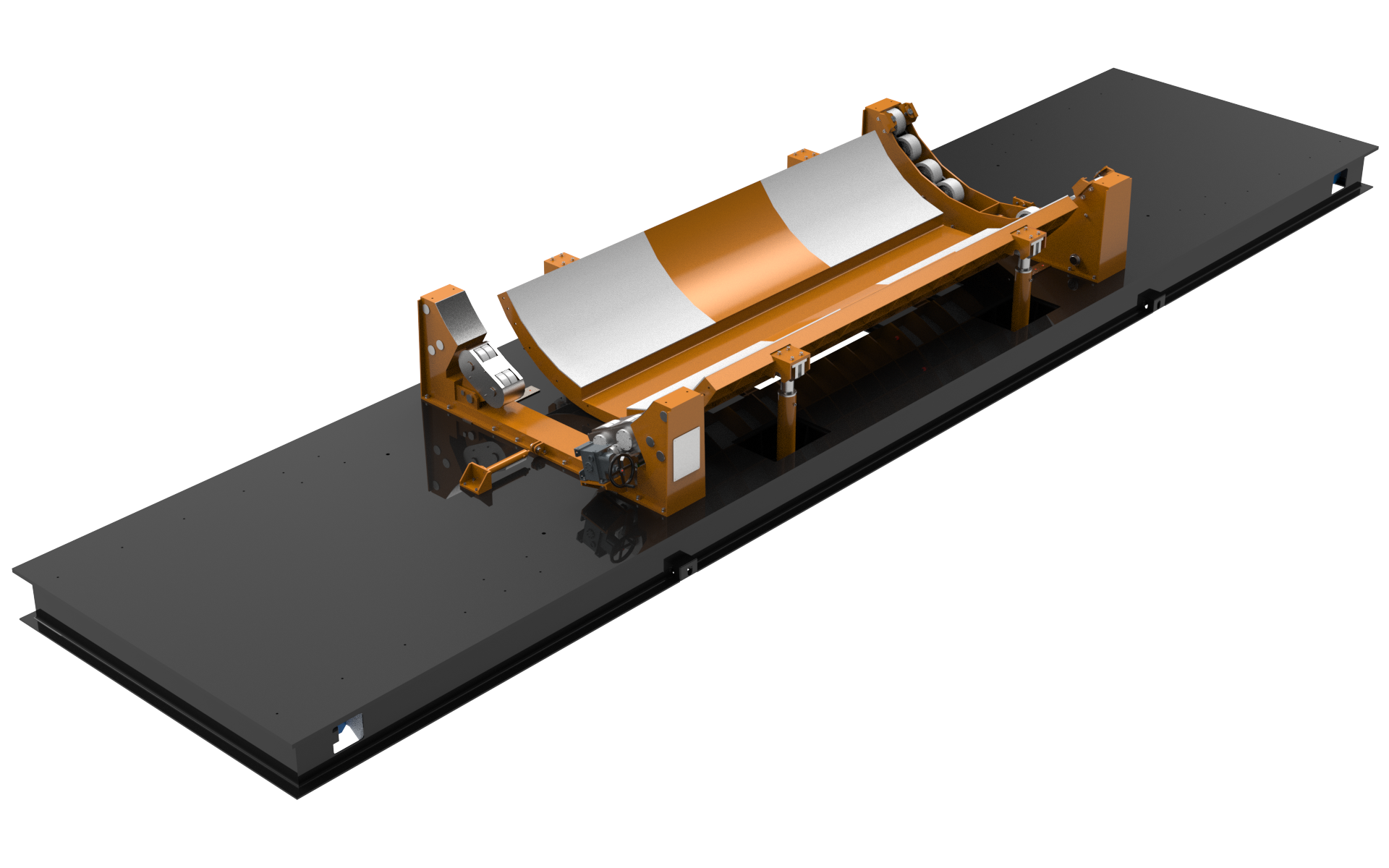

The integration bench is designed for the placement and assembly of a solid rocket booster, with a mass of 45 tons, ensuring their stability and safety of integration operations.

The rubber-covered support saddles are equipped with a hydraulic system that allows vertical translation. The hydraulic system is managed by a control unit equipped with automatic hydraulic power and ATEX electric motor suitable for C0Z2 area.

The rotating saddles of the integration bench are designed to allow controlled positioning of a solid rocket booster, during the integration phases.

Each saddle is sized to support the handling rings of a solid rocket booster, ensuring a safe and stable interface.

All components have a high safety factor to operate in extreme conditions (-10°C to +50°C, humidity 70%).