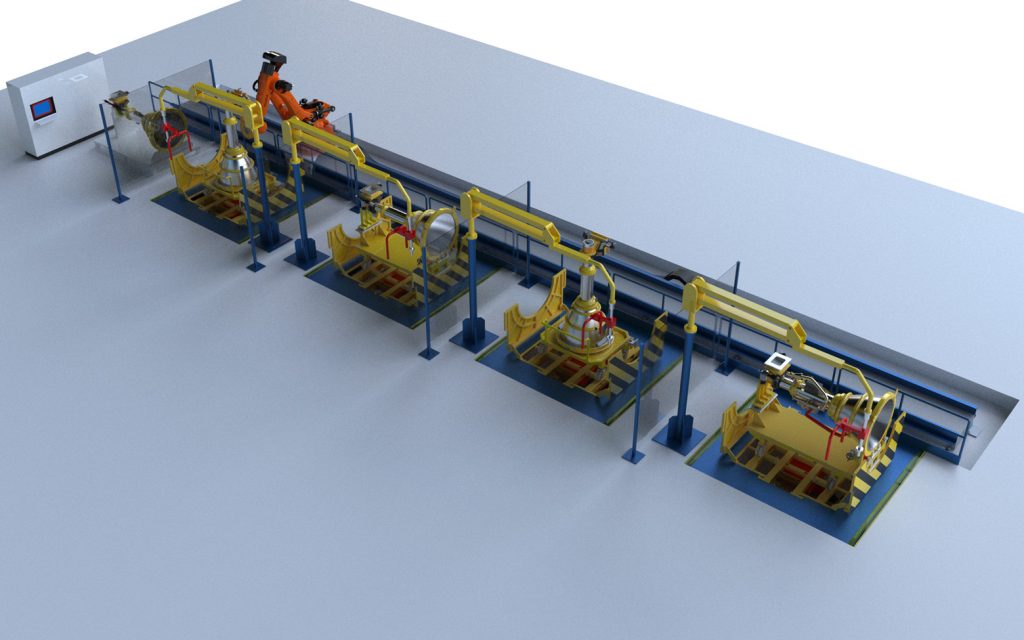

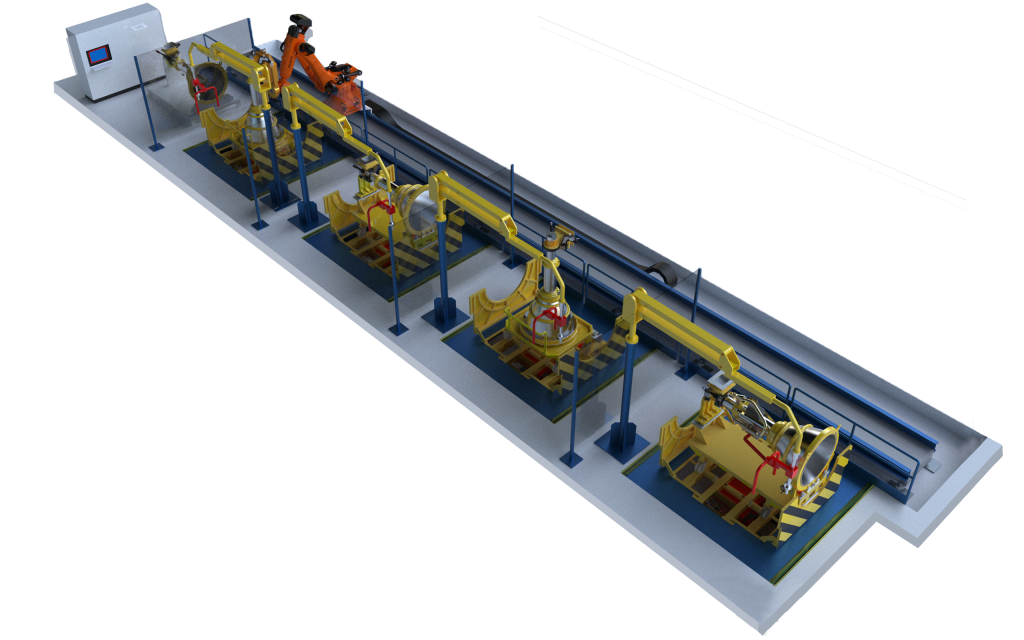

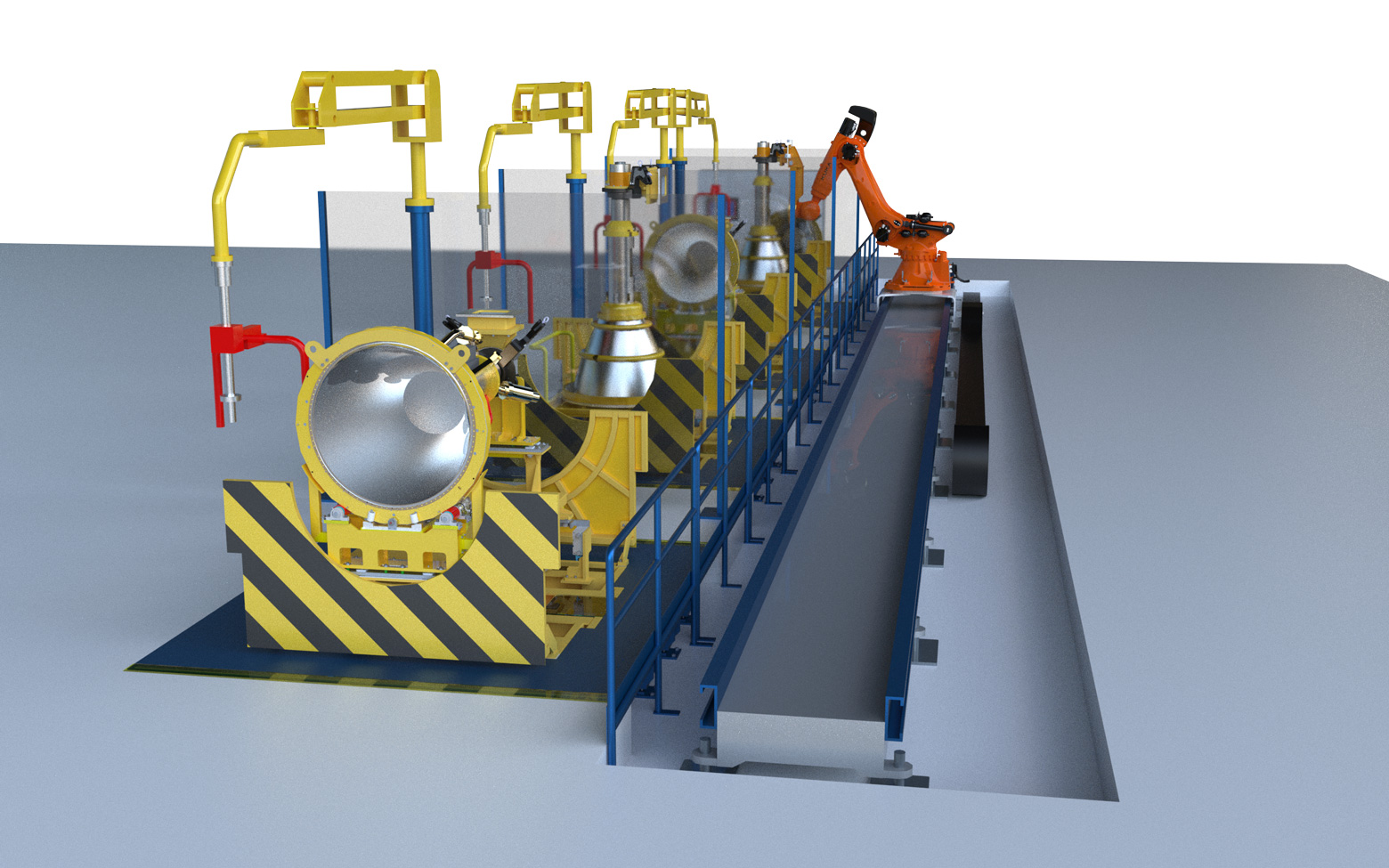

The cryogenic engine assembly line handles all stages of manufacturing and assembly of liquid propellant engines for aerospace use, from component integration, to testing and final packaging.

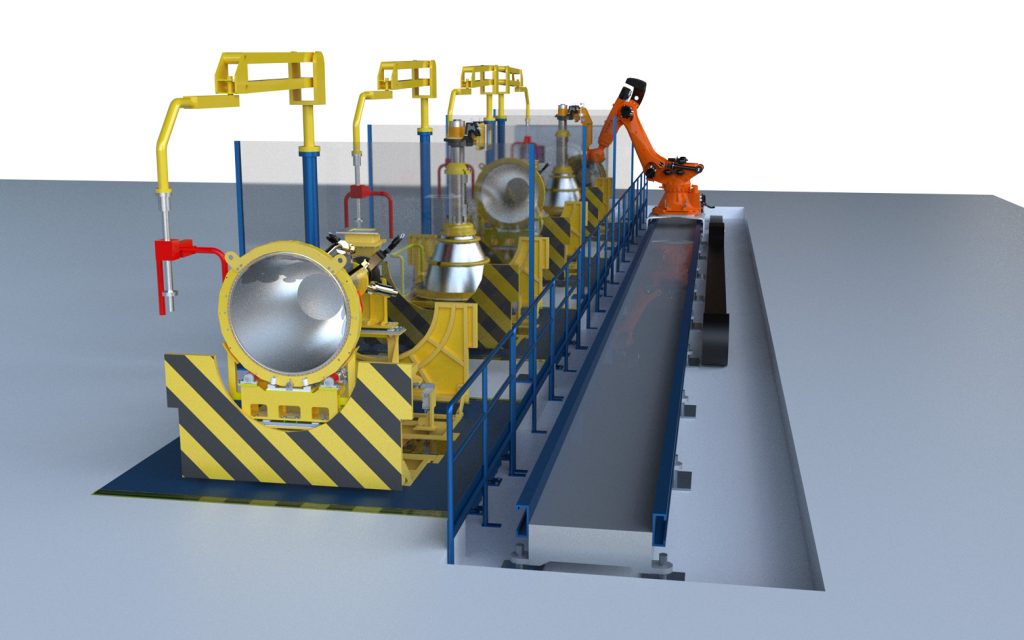

The line is made up of several stations equipped with an anthropomorphic arm that allows the positioning of the liquid propellant engine, with a vertical or horizontal axis in order to facilitate integration operations.

A vertical lift allows the liquid propellant engines to be positioned at different heights depending on the operations to be performed.

An AGV system allows the liquid propellant engines to be moved between the various assembly and packaging stations.

Each station is also equipped with equipment for controlling of assembly and testing operations, such as automatic torque-angle screwdrivers, bar code readers and vision systems.

The line supervision system allows for the traceability and historicization of all operations performed.

This automated approach optimizes assembly and packaging operations, minimizing errors and increasing productivity.