The line is responsible for the production of a sheet of material obtained by coupling a rubber sheet with a Teflon sheet.

The sheet is prepared by interposing a non-stick polyethylene sheet between the various layers thus obtaining a single reel containing the finished product that is ready to be used in the subsequent stages of the production chain.

The machine consists of the three main parts listed below:

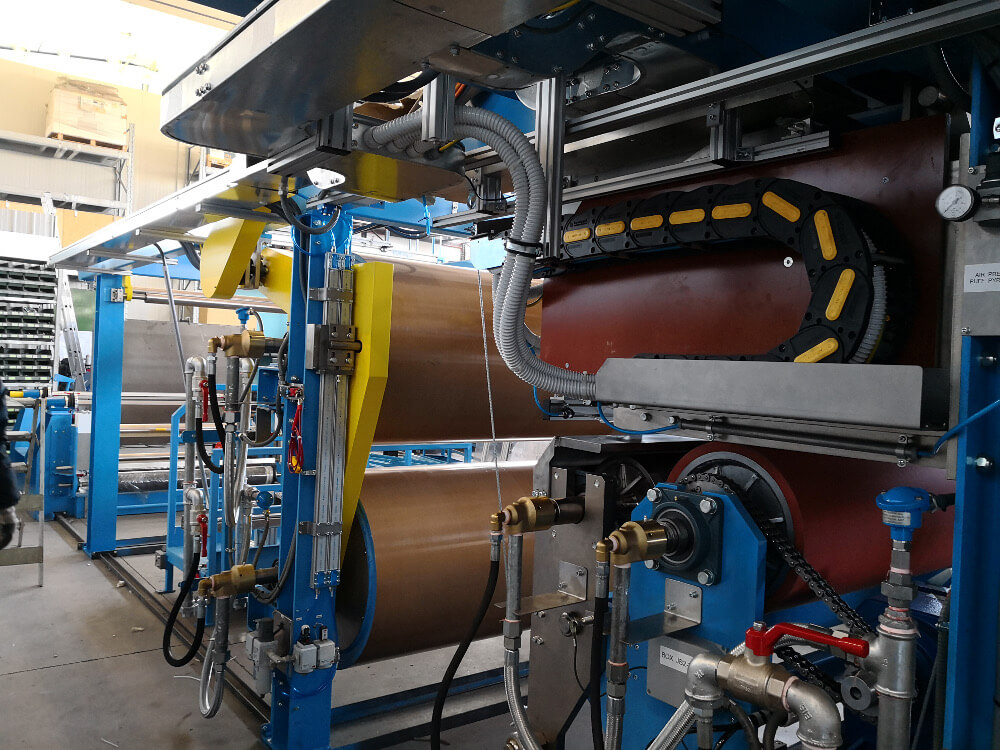

Unwinding unit for processing products

È la The initial part of the machine is made up of three stands.

The first two are loaded with two rubber sheet wrapped rollers.

The Teflon roller sheet is loaded on the third stand and is subsequently coupled and welded with the rubber sheet to obtain the final product.

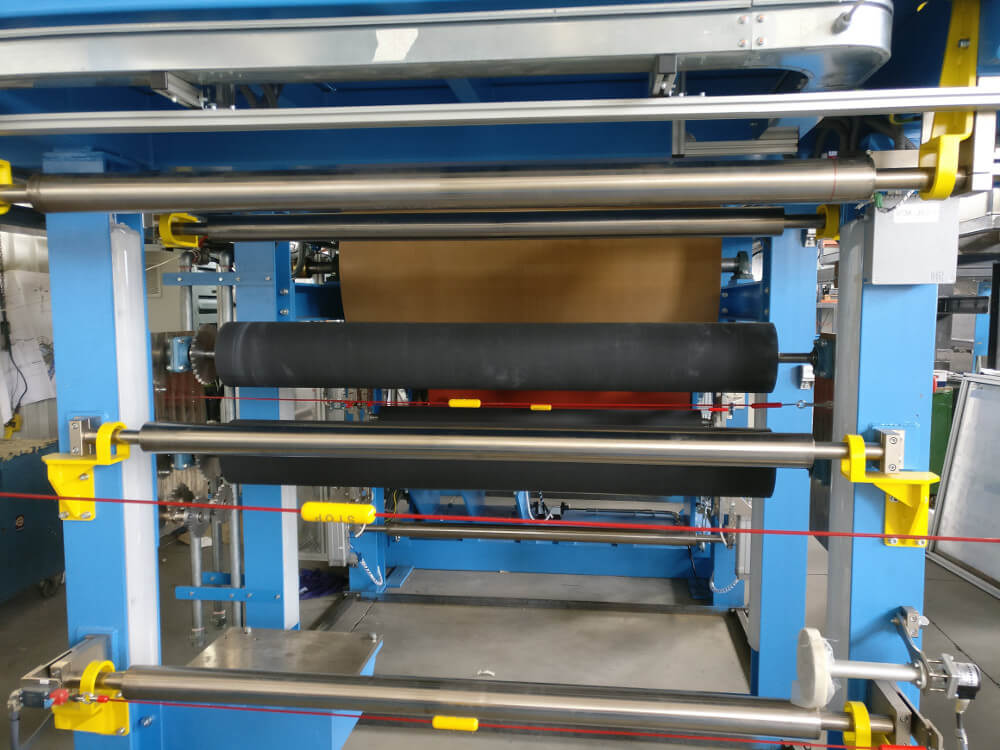

Sheet lamination area

The coupling area is located in the central part of the machine Here the coupling process of the rubber sheet with that of Teflon takes place.

After passing through various preheating and spreading rollers, the materials arrive at the Master Roller inside which, through a series of labyrinth interspaces, the passage of hot water takes place to obtain the heating of the products. In this specific position the materials are coupled together and continue the subsequent operations.

Rewinding unit

It is the final machine of the line and its purpose is to wrap the finished product.

It is a stand-alone structure that includes an idle return roller, a curved fold-out roller and three distinct and separate winding axes.

GALLERY