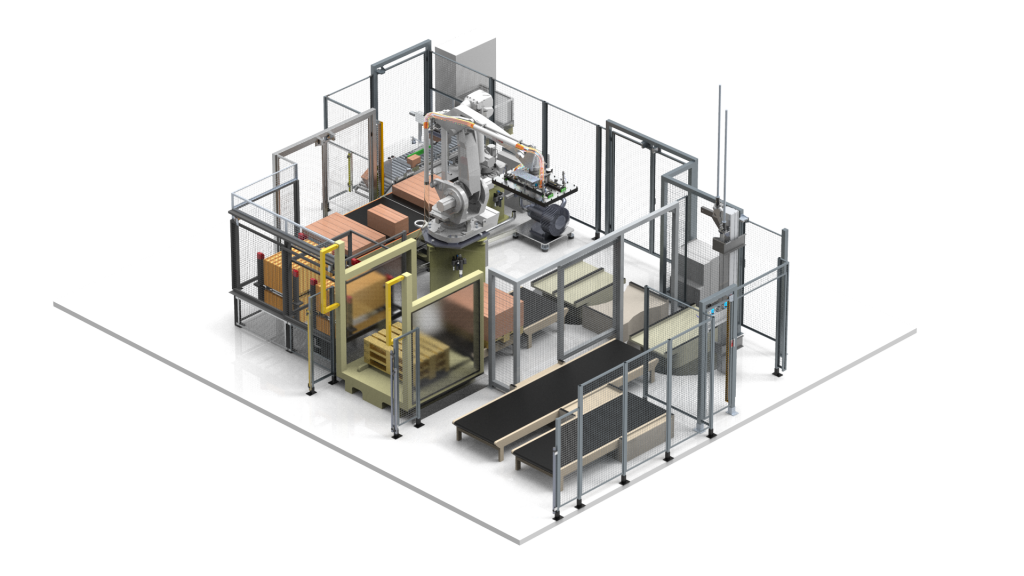

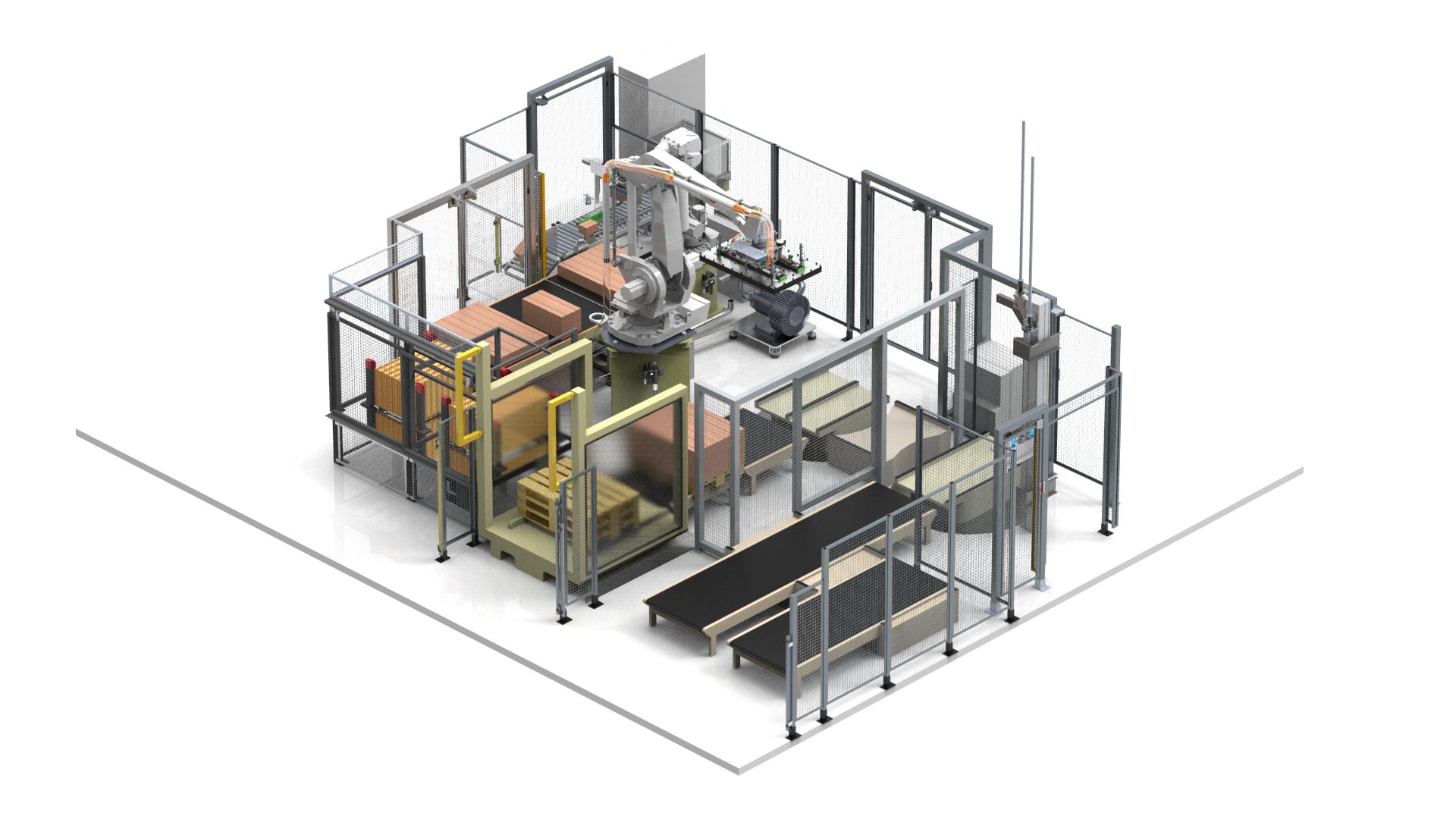

The palletization island is designed and built to palletize diaper boxes and wrap completed pallets.

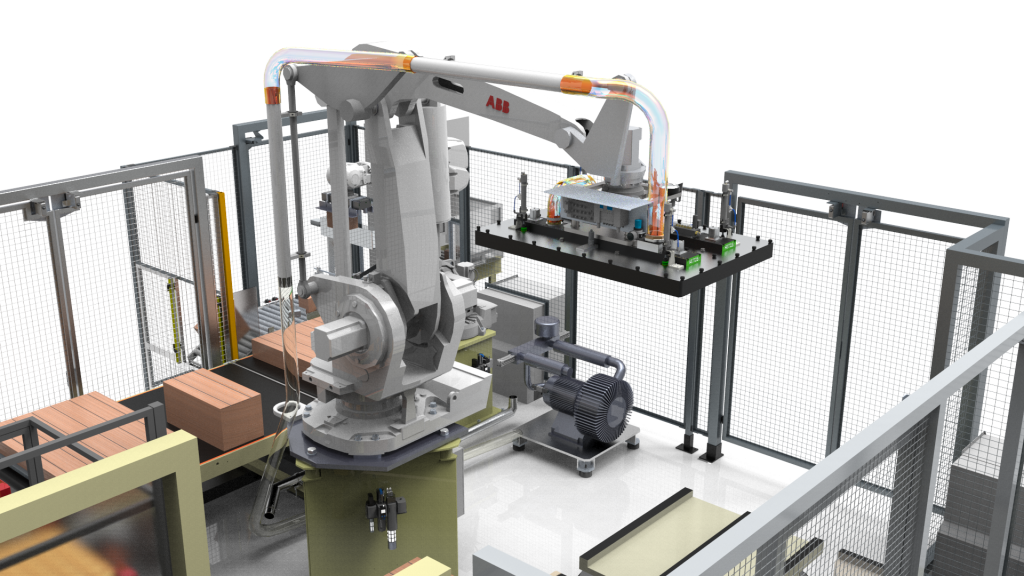

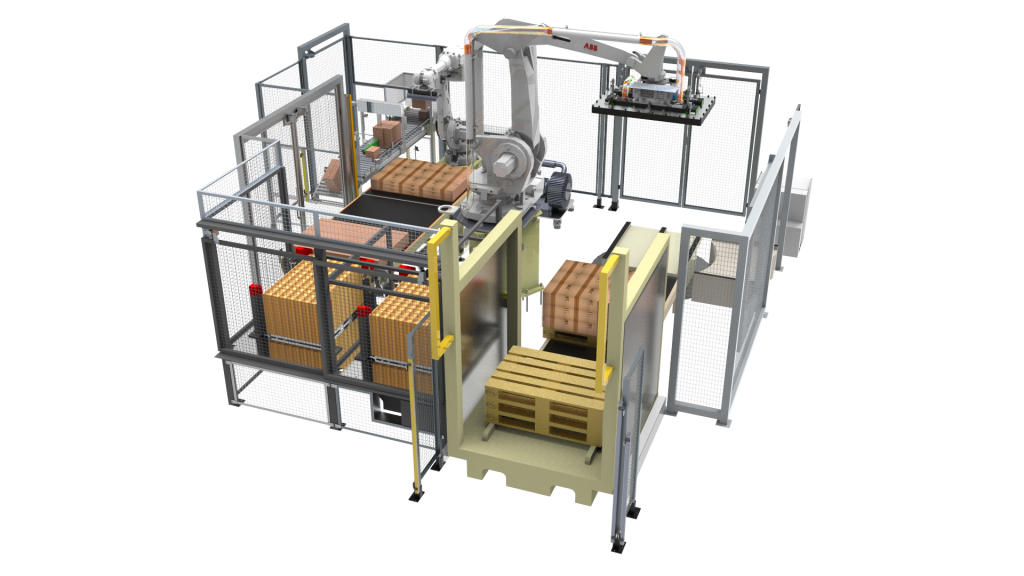

Boxes from the upstream line enter the island via a motorized roller conveyor. The first robot picks up individual incoming boxes and places them on a motorized conveyor belt, forming a layer, which is a row of adjacent cartons that will become a level in the final pallet.

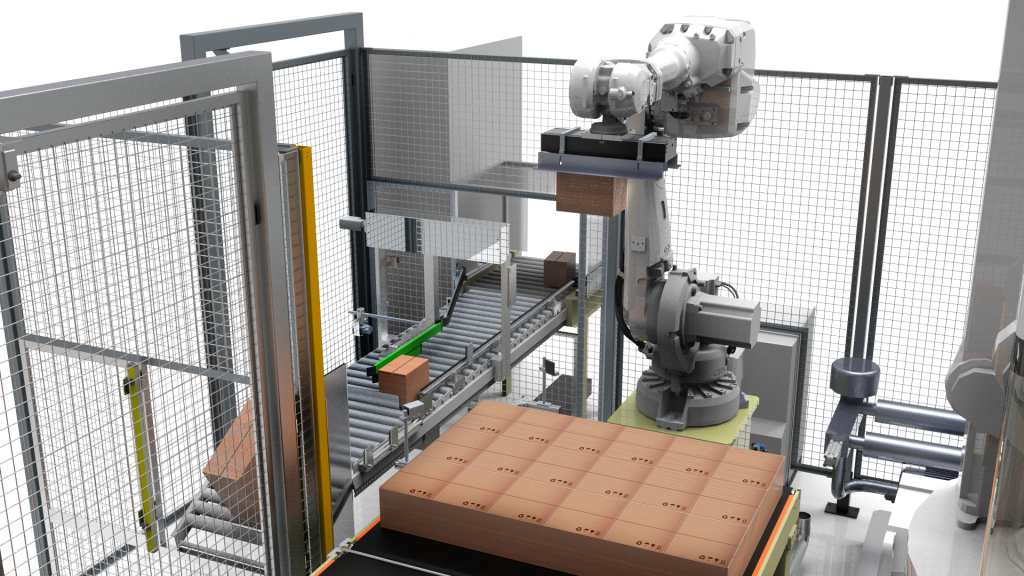

Subsequently, the second robot picks up the entire already-formed layer using a suction gripper tool and places it on a pallet.

The robot repeats this process by vertically stacking the subsequent layers, inserting interlayers taken from the interlayer depot between them.

Once the last layer is deposited on the pallet, it is conveyed via a transport system to a conveyor belt wrapper.

Here, the pallet is wrapped with transparent plastic film.

Later, an automatic label applicator applies the necessary labels for correct product identification.

Once these operations are completed, the pallet proceeds to exit the island using two dedicated conveyor belts.

Pallet retrieval from the belts is done via LGV carts, ensuring a continuous and efficient flow of material in the production line.